Projects

What we did that we are proud of

Calcium Chloride Production Line

Project Impact

The project successfully delivered multiple industrial structures that met the operational needs of a high-demand chemical production line. The combination of concrete and steel systems was engineered for durability, safety, and long-term performance in a harsh industrial environment.

Integrated Structural Engineering for Large-Scale Industrial Hubs

Project Impact

The completed complex provided a rigid, durable, and functionally integrated structure capable of supporting the mechanical and chemical processes of the plant. This work demonstrates the ability to handle large-scale industrial facilities, from detailed structural design to real-world execution.

Light Steel Structures

Project Impact

The project delivered precise, lightweight steel structural systems optimized for industrial performance. The combination of structural design, hands-on fabrication supervision, and real-world installation guaranteed durability, efficiency, and full compliance with engineering and safety standards.

Hydrated Lime Production Line

Project Impact

A fully coordinated and structurally optimized industrial production line capable of supporting high-capacity operations.

The project demonstrates extensive experience in designing integrated equipment-support systems combining reinforced concrete, steel structures, and complex process equipment.

High-Efficiency Poly Aluminum Chloride (PAC) Facility Design

Project Impact

We engineered a modular stainless steel reactor system that maximizes chemical yield while minimizing site footprint. By integrating gravity-fed fluid dynamics, we reduced operational energy costs for the client.

Seismic-Resistant Heavy Steel Skeletal Frameworks

Project Impact

The steel structures were installed with full geometric accuracy, safe load transfer, and proper integration with existing industrial equipment. The final system provided long-term stability and enabled continuous operation of the processing line.

Steel Pipe Racks & Interconnecting Bridges – Chemical Production Facility

Project Impact

Safe and maintainable pipe-rack and bridge system capable of carrying current and future process lines. Reduced steel consumption compared to conventional heavy frames, lowering fabrication and erection costs. Improved access for operators and maintenance teams, and a clear, organized above-ground pipe network.

Precision Structural Drafting for Multi-Phase Industrial Complexes

Project Impact

These drawings represent a wide range of structural drafting and detailing work I prepared for industrial projects, covering steel tanks, equipment foundations, building frames, and complex support assemblies. My focus in these projects was to develop precise, buildable, and fully coordinated drawings that translate engineering design into clear instructions for fabrication and construction.

Forensic Quality Control & Non-Destructive Weld Testing (NDT)

Project Impact

The inspection program ensured that all structural steel components met the required quality level before erection, minimizing site rework and ensuring long-term performance of the structural system under industrial loading conditions.

Certified High-Pressure Storage Systems & Tank Farm Infrastructure

Project Impact

The tanks were constructed with full compliance to engineering tolerances, proper weld integrity, and high corrosion-resistance performance. The fabrication process met all required inspection standards and ensured long-term operational reliability.

Have a complex industrial project? See how our precision engineering can save you time and cost.

Calcium Chloride Production Line – Structural Design & Construction Supervision

This project involved the complete structural design and on-site supervision of multiple facilities within a calcium chloride production line. As the civil and structural lead, my responsibility covered the full lifecycle of engineering tasks—from concept design and analysis to field inspection and construction monitoring.

Scope of Work

1. Structural Design (Concrete & Steel)

- Reinforced concrete foundations for mixing towers, tanks, reactors, and process units

- Octagonal and circular equipment pads

- Curved reinforced concrete retaining and process walls

- Steel structures including industrial sheds, pipe-support frames, and roof systems

- Load calculations considering equipment loads, dynamic loads, and environmental loads

2. Reinforcement Detailing & Field Verification

- Heavy rebar mats for high-demand regions

- Shear-critical zones and column cages

- Anchorage systems for vertical tanks and mechanical equipment

- Inspection of bar spacing, lap splices, development lengths, and cover

3. Industrial Tank Foundations

- Design of foundations for vertical storage and process tanks

- Settlement control and soil-structure interaction considerations

- Alignment and level control prior to tank placement

- Integration of piping corridors and access zones

4. On-Site Supervision & Quality Control

- Continuous inspection during concrete placement

- Verification of formwork stability and dimensional accuracy

- Safety monitoring during construction

- Coordination with mechanical and process teams to ensure alignment with production requirements

Outcome

The project successfully delivered multiple industrial structures that met the operational needs of a high-demand chemical production line. The combination of concrete and steel systems was engineered for durability, safety, and long-term performance in a harsh industrial environment.

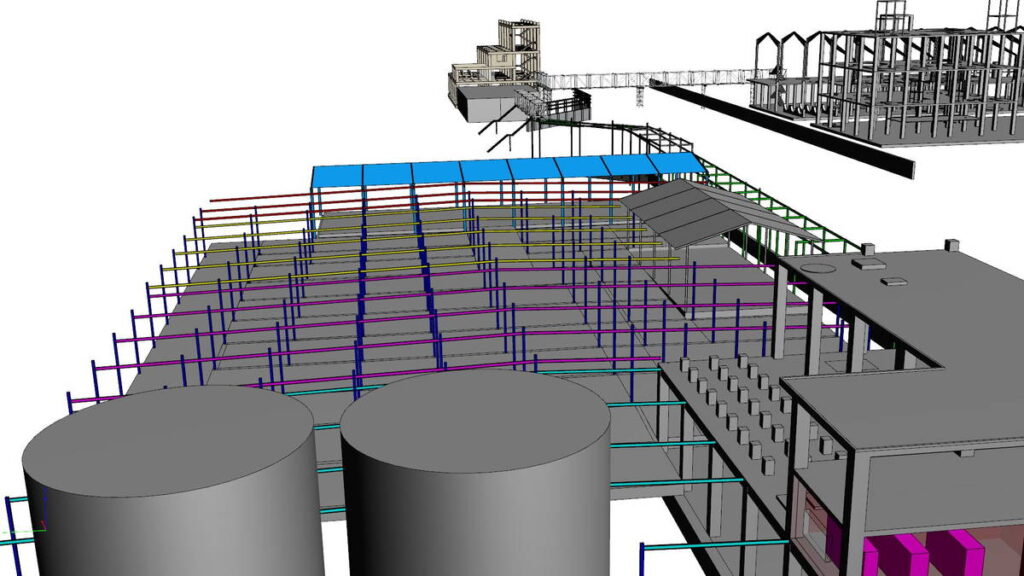

Industrial Complex Design – Structural Engineering & On-Site Supervision

This project represents the complete structural design and supervision of a multi-level industrial complex built to support process equipment, pipe racks, storage units, and chemical production operations. As the civil and structural lead, I managed the engineering cycle end-to-end—from analysis and design to reinforcement inspection and construction oversight.

Scope of Work

1. Structural Design of a Multi-Store Industrial Building

- Reinforced concrete frame with high-capacity columns and beams

- Heavy slab reinforcement for equipment loads, pipe racks, and dynamic forces

- Punching shear checks, heavy mat regions, and congested reinforcement zones

- Integration with mechanical, chemical, and piping layouts

- Load path validation for vertical and horizontal load transfer

2. Reinforcement Detailing & Field Verification

- Highly congested rebar mats in slabs and beams

- Beam-column joints, cage assemblies, and lap splice inspection

- Verification of cover, spacing, bar placement, hooks, and anchorage

- Inspection prior to concrete placement at all levels

3. Industrial Foundations & Process Structures

- Equipment foundations, pump bases, elevated floors, and pipe-support trenches

- Shear walls and core elements for lateral stability

- Design of embedded plates, anchor systems, and base connections

4. Construction Supervision

- On-site monitoring during excavation, formwork, rebar installation, and concrete placement

- Ensuring constructability of heavily reinforced regions

- Coordination with contractors and process engineering teams

- Quality control and compliance with structural drawings and specifications

Outcome

The completed complex provided a rigid, durable, and functionally integrated structure capable of supporting the mechanical and chemical processes of the plant.

This work demonstrates the ability to handle large-scale industrial facilities, from detailed structural design to real-world execution.

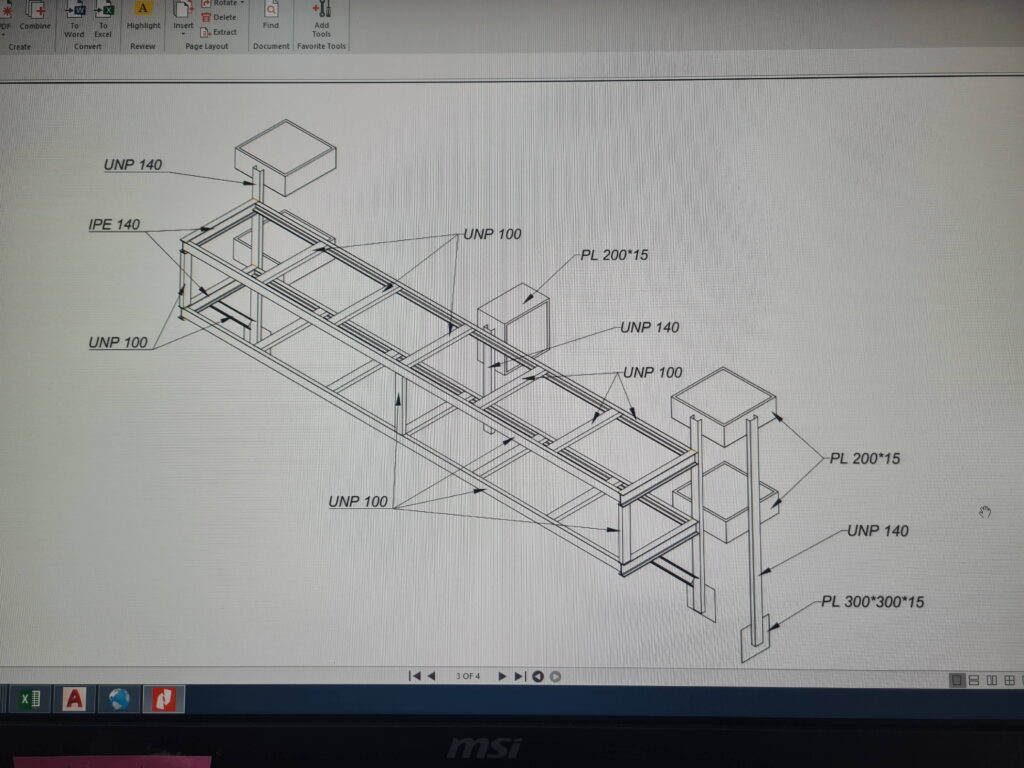

Light Steel Structures – Design, Modeling & Construction Supervision

This project highlights the complete design, modeling, fabrication supervision, and on-site inspection of multiple light steel structural systems. The work included trusses, shade structures, pipe-support frames, modular units, and custom steel assemblies.

Scope of Work

1. Structural Design & Analysis

- Design of light steel trusses using rectangular hollow sections (RHS) and square tubes

- Load evaluation for snow, wind, live loads, and industrial operational demands

- Connection design, including welded joints, gusset plates, and bolted assemblies

- Stability checks for long-span lightweight roofs and canopies

2. 3D Modeling & Coordination

- Development of complete 3D structural models

- Clash detection with adjacent structures and existing equipment

- Modeling of connection details and fabrication-ready geometry

- Coordination with architectural, mechanical, and site constraints

3. Fabrication Supervision

- Inspection of cutting, welding, alignment, and fit-up

- Quality control for weld thickness, continuity, and joint preparation

- Verification of truss assemblies before painting and installation

- Ensuring fabrication accuracy according to design drawings

4. On-Site Assembly & Installation

- Supervision of truss lifting, positioning, and final alignment

- Inspection of anchors, base plates, and installation tolerances

- Safety coordination during erection

- Resolution of field issues and constructability adjustments

Outcome

The project delivered precise, lightweight steel structural systems optimized for industrial performance. The combination of structural design, hands-on fabrication supervision, and real-world installation guaranteed durability, efficiency, and full compliance with engineering and safety standards.

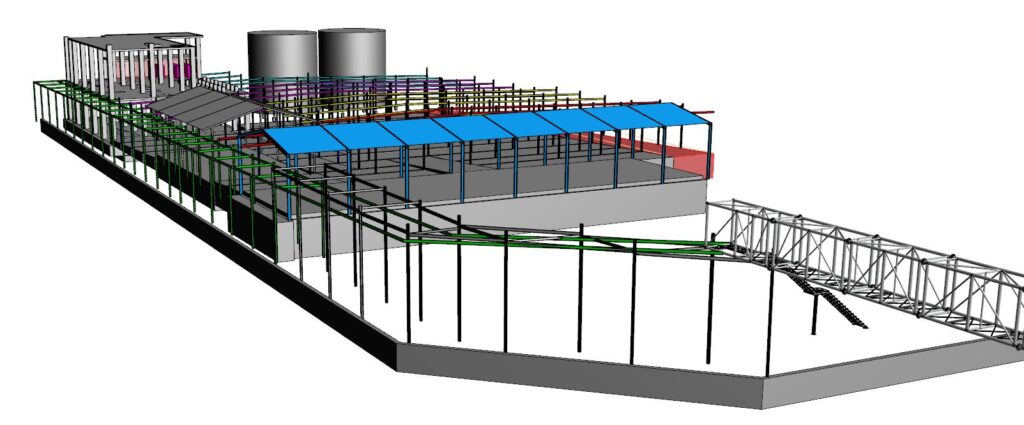

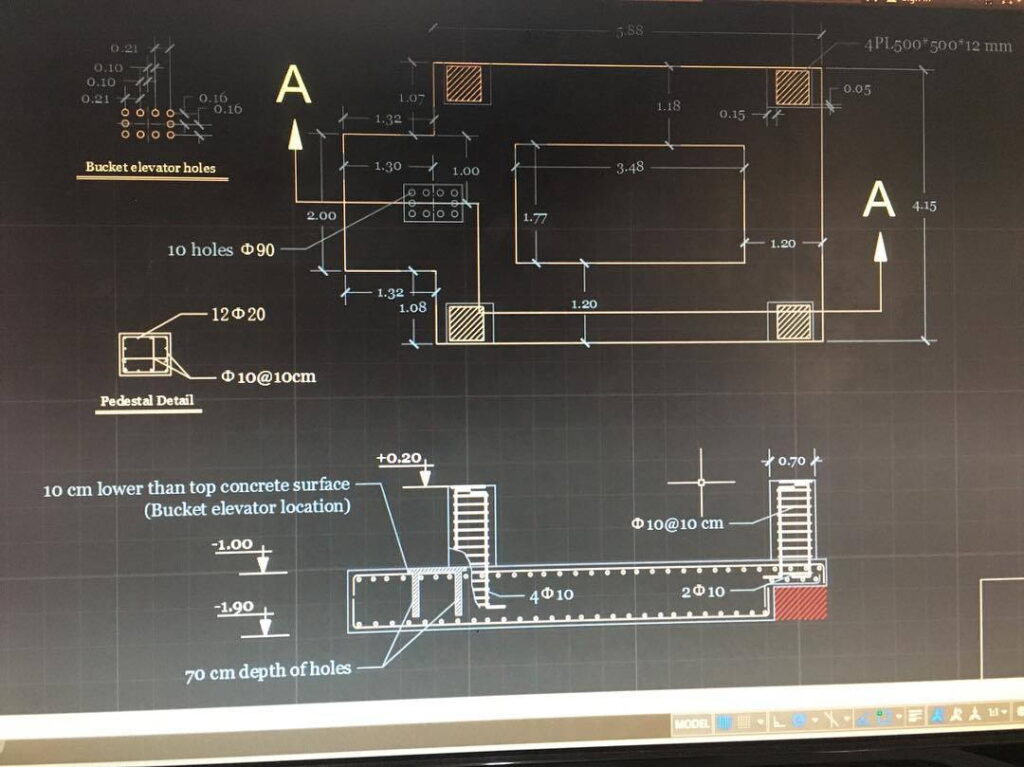

Hydrated Lime Production Line – Structural & Equipment Support Engineering

This project involved the complete engineering, structural design, and supervision of a full-scale hydrated lime production line. The scope covered site planning, review and coordination of mechanical equipment layouts, and the structural design of heavy foundations and steel support systems.

Scope of Work

1. Site Planning & Equipment Layout Coordination

- Development of the overall site plan for the production line

- Reviewing mechanical and process equipment drawings, including:

- Jaw crushers and large industrial crushers

- Rotary kiln (horizontal)

- Cooling units

- Bag filter systems

- Bucket elevators

- Screeners and vibratory units

- Belt and screw conveyors

- Ensuring proper equipment spacing, alignment, load transfer, and access zones

2. Structural Design of Heavy Foundations

- Reinforced concrete pits and deep foundations for crushers

- Heavy-duty RC foundations for the rotary kiln and horizontal cooler

- Design of vibration-resisting blocks and isolated machine foundations

- Structural detailing for retaining walls, trenches, and underground access zones

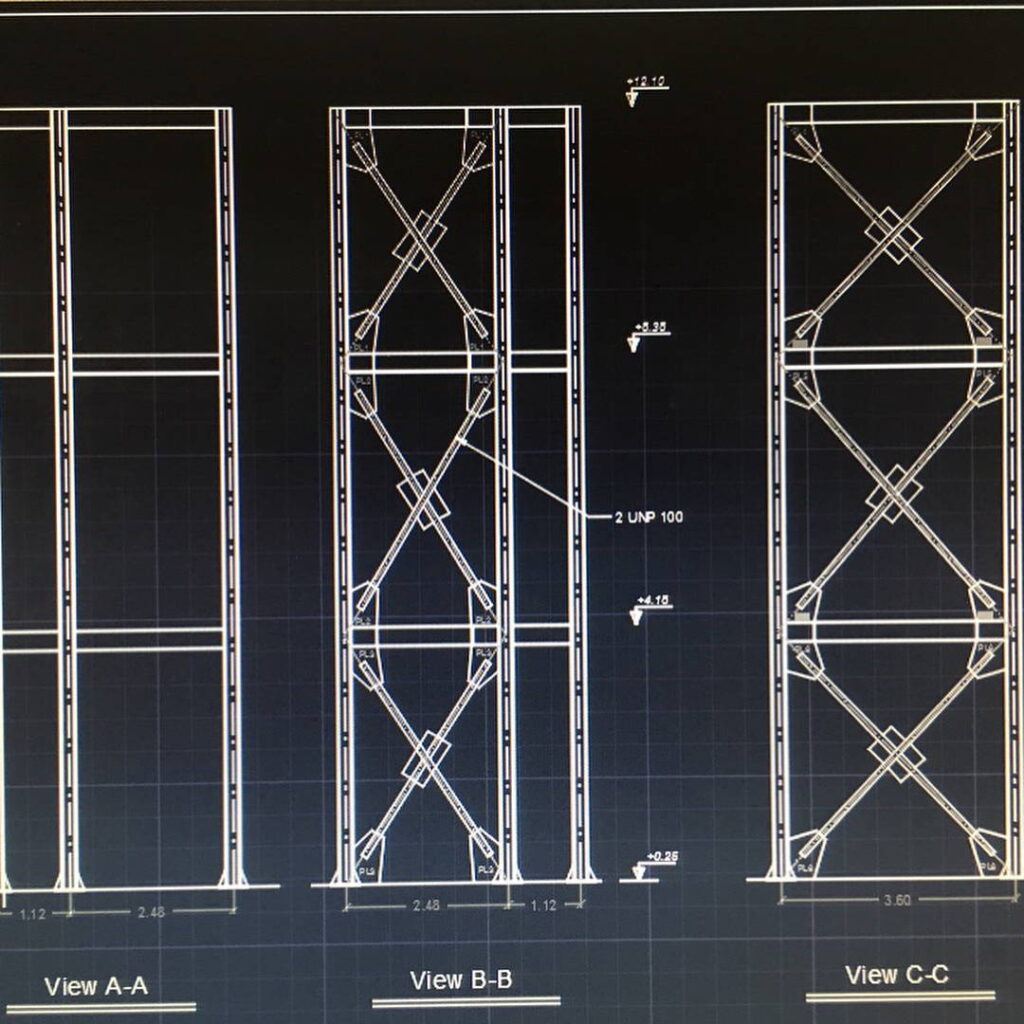

3. Steel Support Structures

- Structural design of steel frames supporting elevated equipment

- Tower structure for large industrial hoppers and storage units

- Steel structures for conveyors, platforms, access walkways, and operator routes

- Design of bracings, anchorage systems, and load distribution assemblies

4. On-Site Construction Supervision

- Verification of rebar placement, concrete formwork, and structural detailing

- Supervision of installation of crushers, rotary kiln components, hoppers, and conveyors

- Monitoring lifting operations for heavy equipment

- Ensuring structural–mechanical compatibility during installation

- Field problem-solving and constructability optimization

Outcome

A fully coordinated and structurally optimized industrial production line capable of supporting high-capacity operations.

The project demonstrates extensive experience in designing integrated equipment-support systems combining reinforced concrete, steel structures, and complex process equipment.

Poly Aluminum Chloride (PAC) Production Line – Dryer Vessel Construction & Structural Engineering

This project showcases the full-scale construction supervision, welding inspection, and structural design for a 12-meter industrial dryer vessel used in a Poly Aluminum Chloride (PAC) production facility. The dryer, fabricated from stainless steel plates, was assembled layer by layer inside a multi-story reinforced concrete tower.

Scope of Work

1. Construction Supervision of a 12-Meter Stainless Steel Dryer Vessel

- Overseeing day-to-day construction activities with more than 30 workers on-site

- Managing four TIG welding teams working simultaneously

- Layer-by-layer fabrication of the vessel, assembled progressively from the bottom upwards

- Monitoring alignment, fit-up, weld sequencing, and safety procedures

- Ensuring plate curvature accuracy and structural continuity during vertical lifting

- Quality control for TIG welds, including root pass, penetration, and finish quality

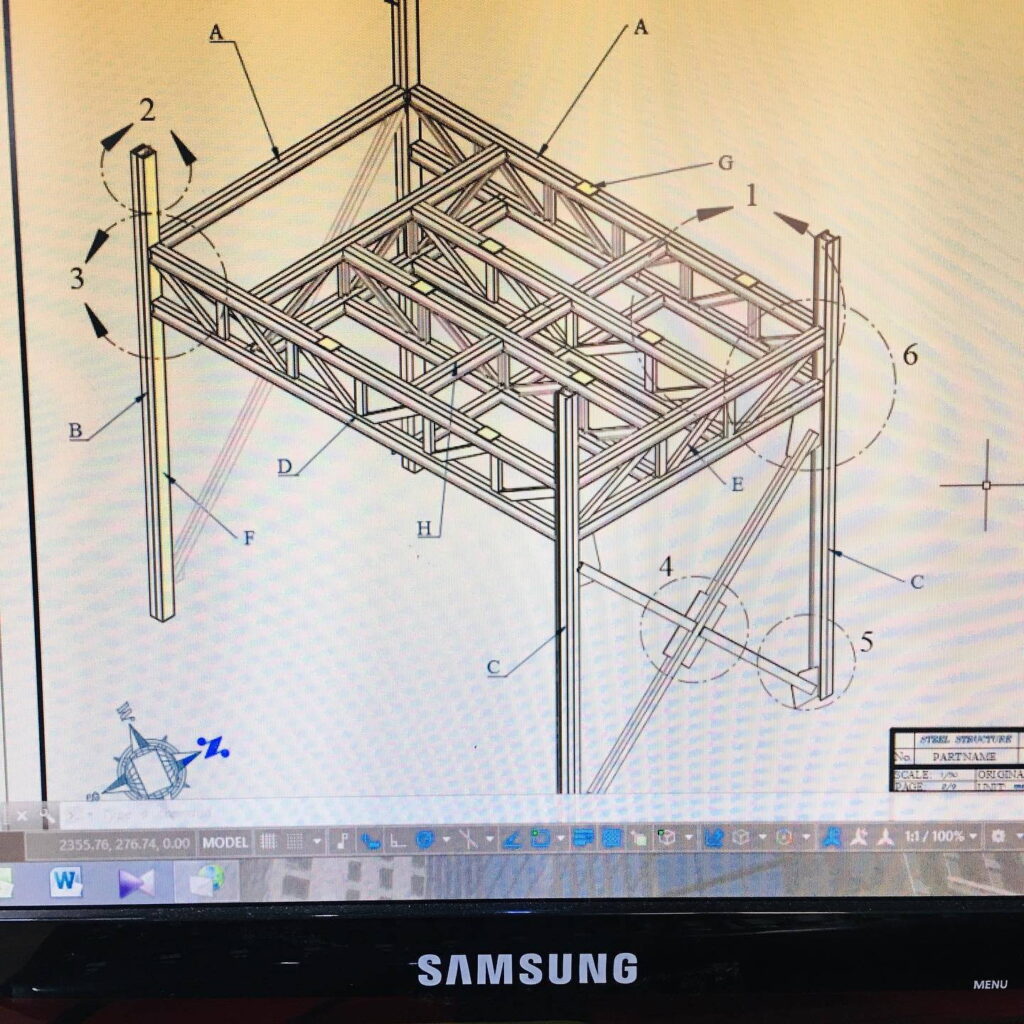

2. Structural Engineering of the Upper Steel Framework

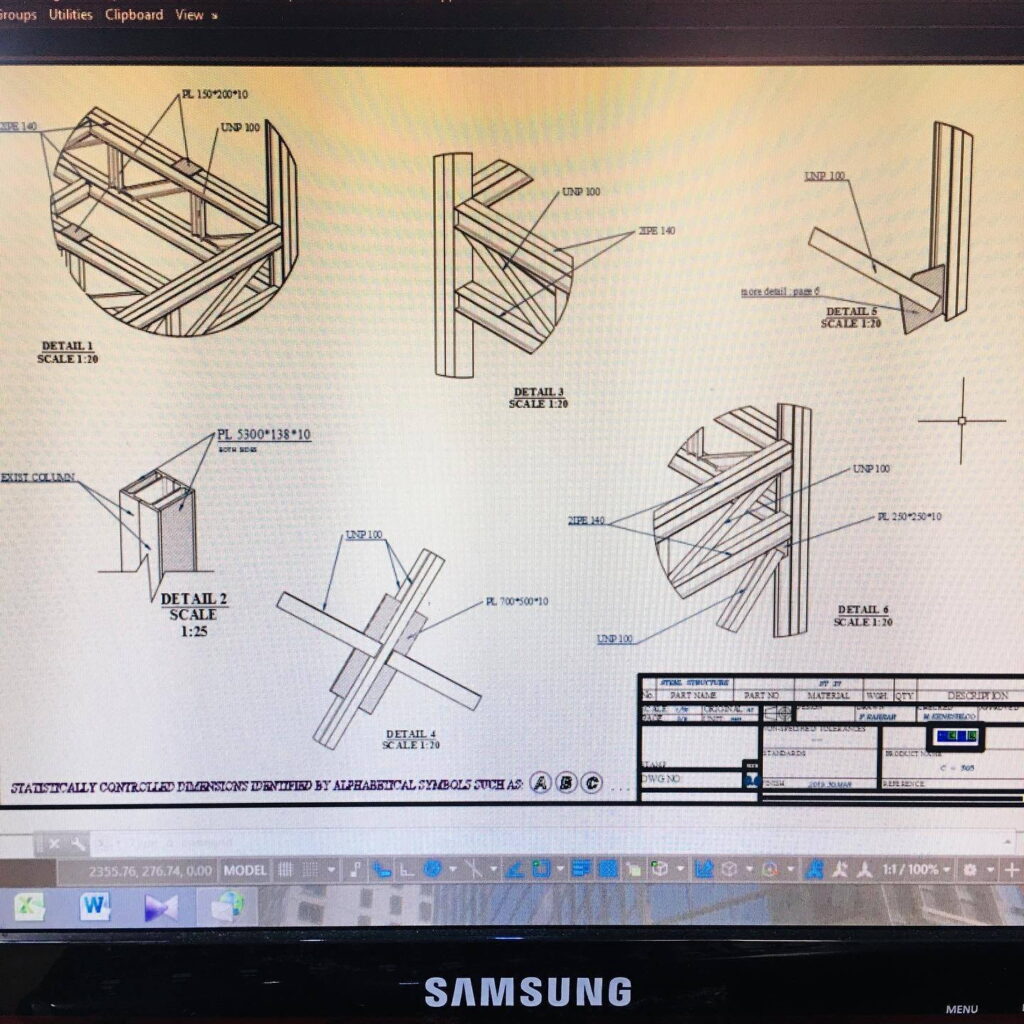

- Full design and detailing of the steel truss system installed above the concrete tower

- Engineering of circular roof framing, radial beams, and access structures

- Coordination between mechanical requirements of the dryer and structural load paths

- Detailing of bracings, stiffeners, anchorage plates, and support rings

3. Integration with the Concrete Tower Structure

- Reviewing the interaction between the RC tower and the internal steel vessel

- Ensuring compatibility between structural openings, lifting paths, and assembly tolerances

- Verifying load transfer from the vessel to the concrete frame

- Supervising all penetrations, embedded plates, and equipment access points

4. On-Site Quality Assurance

- Daily inspection of welds, joints, and plate installation

- Verification of circularity and dimensional tolerances at each construction stage

- Coordination with cranes, rigging teams, and material handling operations

- Providing technical resolutions for field issues during construction

Outcome

The project successfully delivered a large-scale stainless steel dryer built under continuous supervision and engineered for long-term industrial performance.

The combination of structural design, advanced welding inspection, and rigorous construction management ensured precise execution of one of the most complex components in the PAC production line.

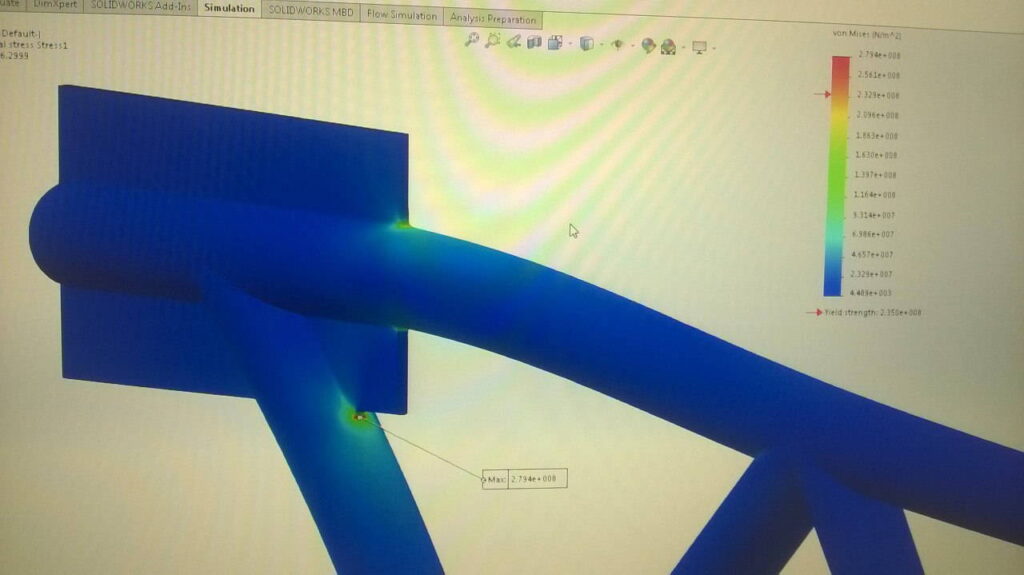

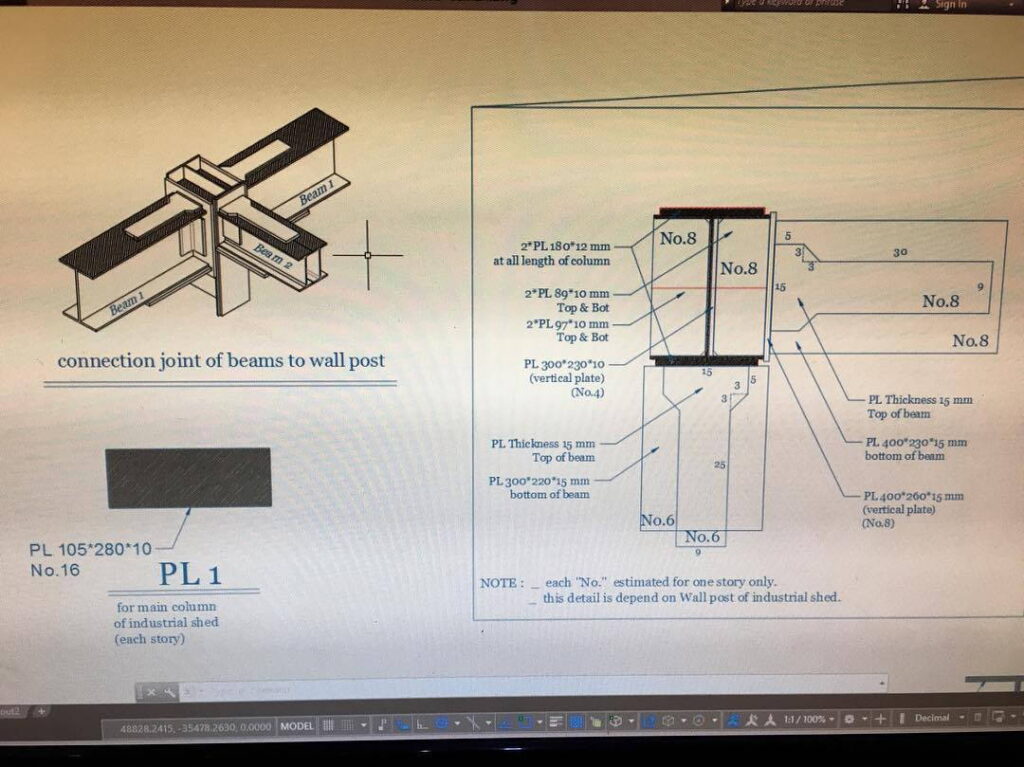

Industrial Steel Structures – Precision Design & Execution Supervision

Scope of Work

This project involved the structural design, detailing, and construction supervision of several interconnected steel structures used in industrial material-processing lines. The work required exceptionally high precision, as many components had to be assembled inside or on top of each other with minimal tolerance for error.

Key Engineering Challenges

- Nested Structures:

Designing a vibration-control chamber (“calming room”) that was installed inside an independent steel frame. - High-Elevation Installations:

Supporting a hopper at a high elevation where no independent support was available — requiring a custom load-transfer design connected directly to the main lime-storage hopper. - Non-standard Geometry & Load Paths:

Each hopper and chute imposed concentrated loads, requiring specific bracing configurations and custom connections. - Congested Industrial Environment:

Limited access, existing equipment, and operational constraints demanded highly coordinated detailing.

Engineering Solutions

- Full 3D structural modelling of frames, bracings, and connection assemblies

- Development of detailed shop drawings with exact cuts, plates, and welds

- Custom load-transfer design between independent structures

- Field supervision during fabrication, welding, alignment, and final installation

- Immediate troubleshooting of misalignments and tolerance issues

Final Outcome

The steel structures were installed with full geometric accuracy, safe load transfer, and proper integration with existing industrial equipment. The final system provided long-term stability and enabled continuous operation of the processing line.

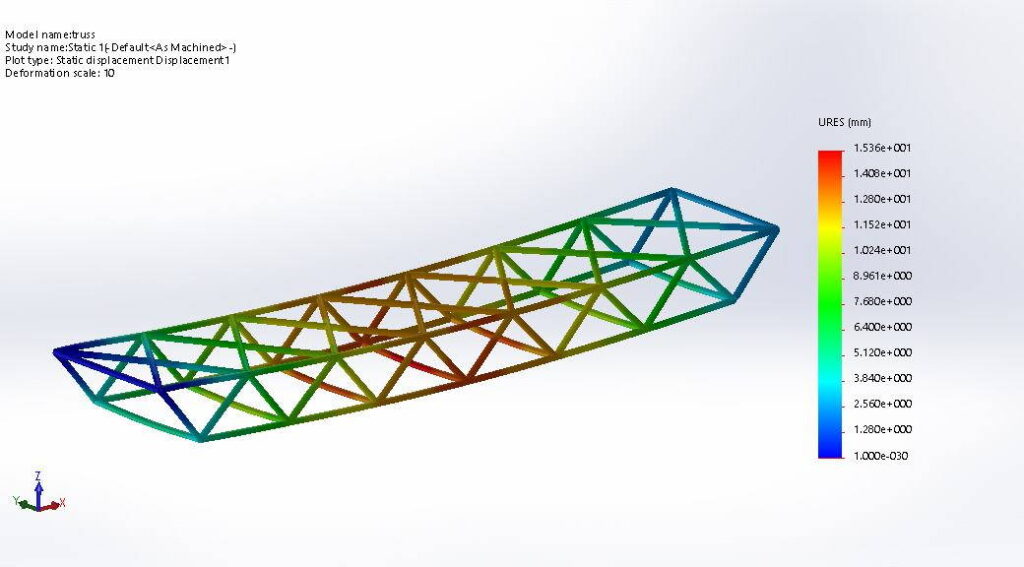

Steel Pipe Racks & Interconnecting Bridges – Chemical Production Facility

Scope of Work

- Structural design of multi-level steel pipe racks and interconnecting access bridges.

- 3D modeling of framing, truss systems, and supports for pipes, cable trays, and walkways.

- Detailing of connections, support brackets, base plates, and corrosion-protection systems.

- On-site supervision during fabrication, erection, alignment, and final inspection.

Engineering Challenges

- High concentration of chemical vapors and risk of aggressive corrosion.

- Limited available space for routing multiple pipe lines at different elevations.

- Need to keep steel tonnage under control while maintaining stiffness and serviceability.

- Installation over existing live units with tight shutdown windows.

Engineering Solutions

- Used optimized tubular and channel sections to achieve lightweight yet stable pipe-rack frames.

- Designed long-span steel truss bridges to cross roads and equipment areas without interfering with operations.

- Verified deflection, stability, and member forces through 3D analysis and truss simulations.

- Specified suitable coating systems and detailing (drainage, seal welding, access for maintenance) for long-term durability.

- Coordinated routing and support locations with mechanical and process teams to eliminate clashes and simplify erection.

Outcome

Improved access for operators and maintenance teams, and a clear, organized above-ground pipe network.

Safe and maintainable pipe-rack and bridge system capable of carrying current and future process lines.

Reduced steel consumption compared to conventional heavy frames, lowering fabrication and erection costs.

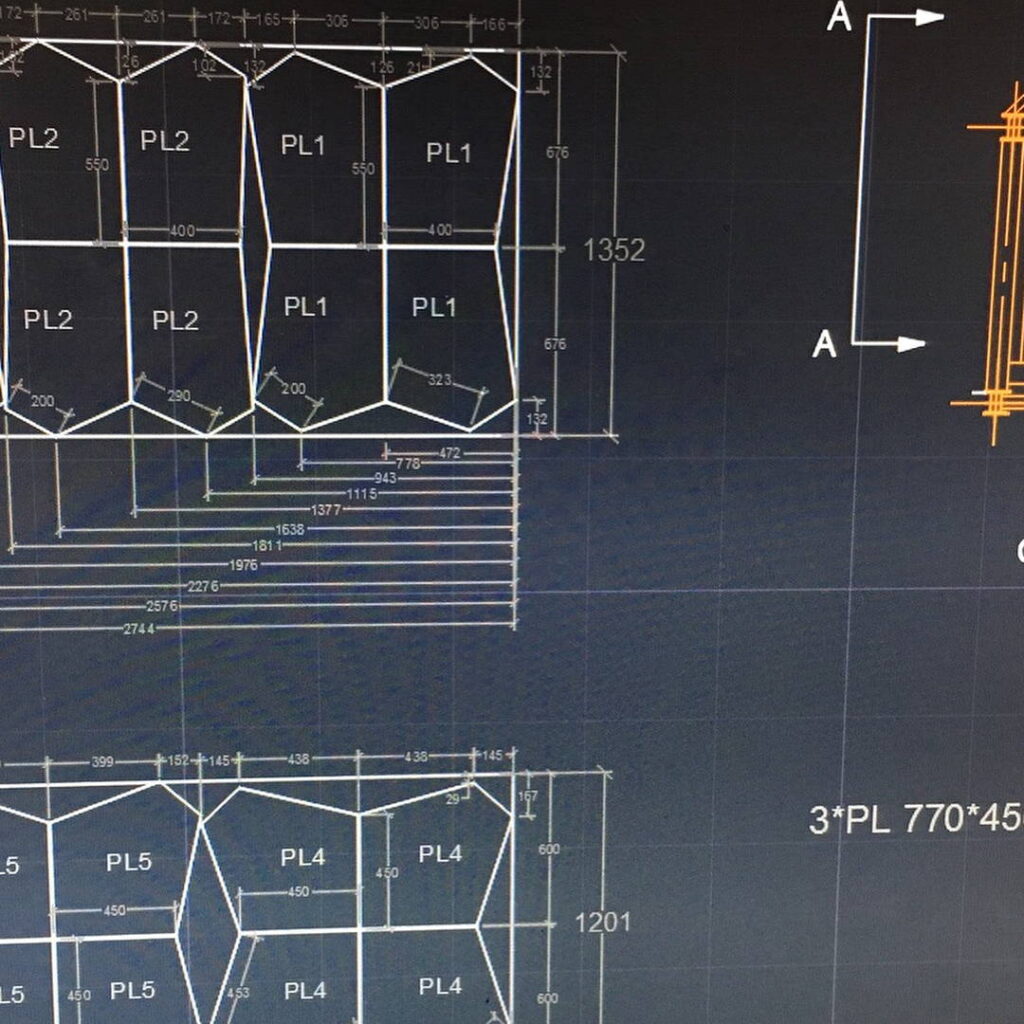

Structural Drafting & Steel/Concrete Detailing

These drawings represent a wide range of structural drafting and detailing work I prepared for industrial projects, covering steel tanks, equipment foundations, building frames, and complex support assemblies. My focus in these projects was to develop precise, buildable, and fully coordinated drawings that translate engineering design into clear instructions for fabrication and construction.

Key Capabilities Highlighted in These Samples:

• Steel Detailing – Connection design, plate development, stiffener layouts, anchor bolt plans, bracing systems, and 3D-assisted connection detailing.

• Reinforced Concrete Drafting – Foundation plans, sections, reinforcement layouts, embed plates, sleeves, and construction sequencing.

• Fabrication-Ready Drawings – Shop drawings for tanks, hoppers, stair towers, and steel frames with full dimensional accuracy.

• Coordination With Field Conditions – Adjusting designs to real site constraints, interference checks, elevation conflicts, and constructability considerations.

• Drafting Standards

- Clear layering and line-weight control

- Proper dimensioning and detailing hierarchy

- Accurate sectioning and referencing

- Consistent annotation and fabrication notes

- Clash-free detailing with emphasis on assembly sequence

These drawings were part of multidisciplinary packages where accuracy directly impacted fabrication, assembly speed, safety, and project cost.

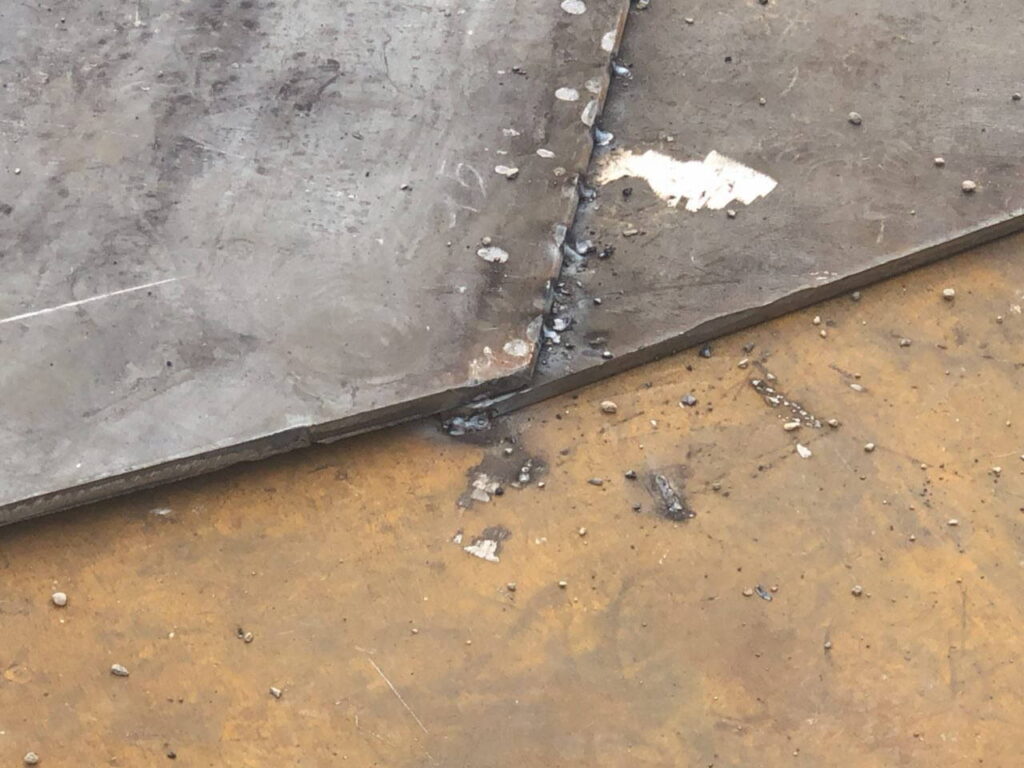

Steel Structure Weld Inspection & Quality Control

This project involved the comprehensive inspection and quality assurance of welded steel components prior to installation in an industrial structural system. The scope included nondestructive testing (NDT), visual examinations, and verification of fabrication accuracy based on project specifications and engineering standards.

Scope of Work

- UT (Ultrasonic Testing) on critical welds in girders and built-up sections

- PT (Liquid Penetrant Testing) for surface crack detection

- VT (Visual Testing) for overall weld geometry, bead continuity, and workmanship

- Inspection of stiffeners, connection plates, web-to-flange welds, and support brackets

- Verification of plate preparation, bevel angles, cleaning, and defect removal

- Assessment of weld accessibility and fit-up prior to welding operations

Key Inspection Procedures

- Ultrasonic Testing (UT):

Used for detecting internal discontinuities including lack of fusion, slag inclusions, and root defects in full-penetration welds. - Liquid Penetrant (PT):

Applied to identify surface-breaking flaws on fillet welds, corner welds, and plate edges—especially in highly stressed regions. - Visual Testing (VT):

Included checking weld size conformity, heat-affected zones, undercut, porosity, overlap, and overall uniformity. - Fit-Up & Pre-Weld Checks:

Alignment, root gap measurement, tack weld quality, backing alignment, and cleanliness of surfaces.

Technical Emphasis

- Inspection of complex fabricated sections including large plate girders

- Evaluation of welded stiffener systems designed to transfer vertical and lateral loads

- Ensuring weld profiles matched design requirements for fatigue resistance

- Confirming dimensional tolerance of fabricated elements prior to site assembly

- Documentation of findings, non-conformities, and corrective actions

Final Outcome

The inspection program ensured that all structural steel components met the required quality level before erection, minimizing site rework and ensuring long-term performance of the structural system under industrial loading conditions.

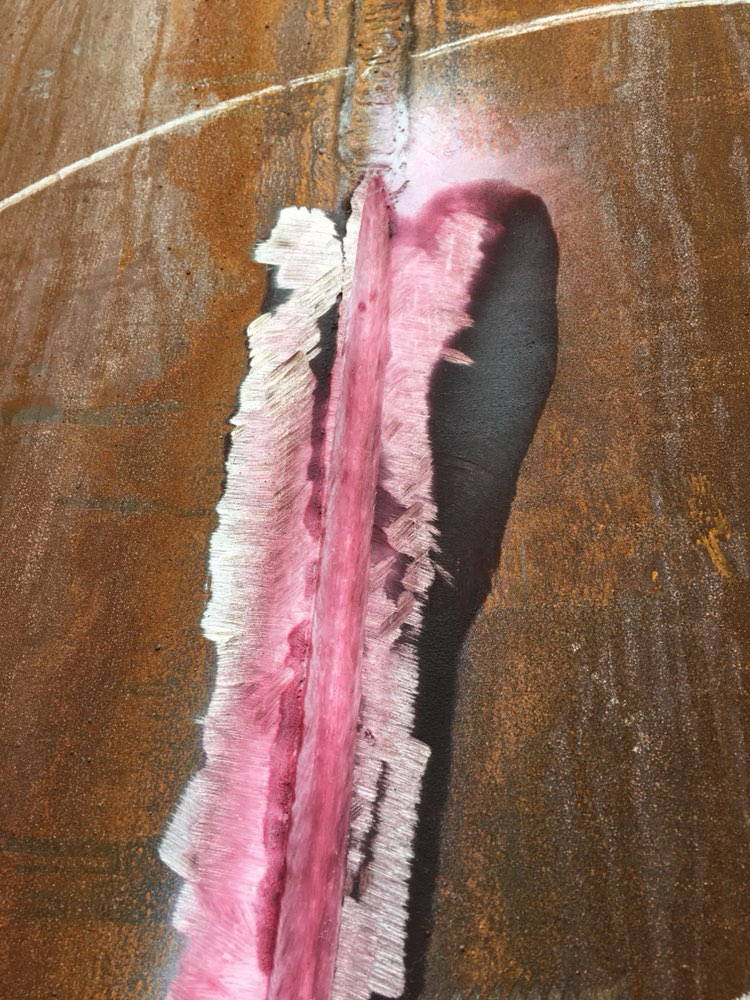

Industrial Storage Tanks – Welding Inspection & Construction Supervision

Scope of Work

The project involved full supervision and inspection during the fabrication of large liquid calcium chloride storage tanks (capacity ~526 m³ each, diameter 12 m, height 12 m). The work covered base plate installation, shell assembly, girder installation, and multilayer welding of all circumferential and vertical seams.

Engineering Challenges

- High-precision fit-up:

Large-diameter tanks require strict control over out-of-roundness and plate alignment. - Chemical exposure requirements:

Tanks storing liquid calcium chloride demand high weld quality and reliable corrosion protection. - Heavy lifting & sequencing constraints:

Shell courses, stiffeners, and platforms needed coordinated installation with limited onsite space. - Foundation and anchorage alignment:

Precise positioning of anchor bolts and bottom plates was critical to long-term performance.

Inspection & Quality Control Procedures

- Fit-up inspection of shell plates and bottom plates

- Verification of verticality and roundness tolerances

- Inspection of root pass, hot pass, and fill passes

- Monitoring electrode type, welding parameters, and interpass temperature

- Visual Testing (VT) for every weld segment

- Dye Penetrant Testing (PT) on critical areas (photos confirm this)

- Control of distortion, shrinkage, and sequencing

- Inspection of stiffener welding, brackets, and supports

- Final acceptance of weld continuity and surface finishing

Outcome

The tanks were constructed with full compliance to engineering tolerances, proper weld integrity, and high corrosion-resistance performance. The fabrication process met all required inspection standards and ensured long-term operational reliability.